If you’ve ever wondered what manufactured wood is, then welcome to the club. Solid and engineered wood are just some of the various concepts in furniture making. So, many woodworkers still struggle with making the best decision for their projects.

Even when wood enthusiasts are familiar with manufactured wood, they still have questions about its durability and sustainability. For instance, before sandblasting wood, carpenters note the wood surface to help them know what to expect.

Read on to explore manufactured wood, how it is made, and the common uses of manufactured wood in the workshop.

What Does Manufactured Wood Really Mean?

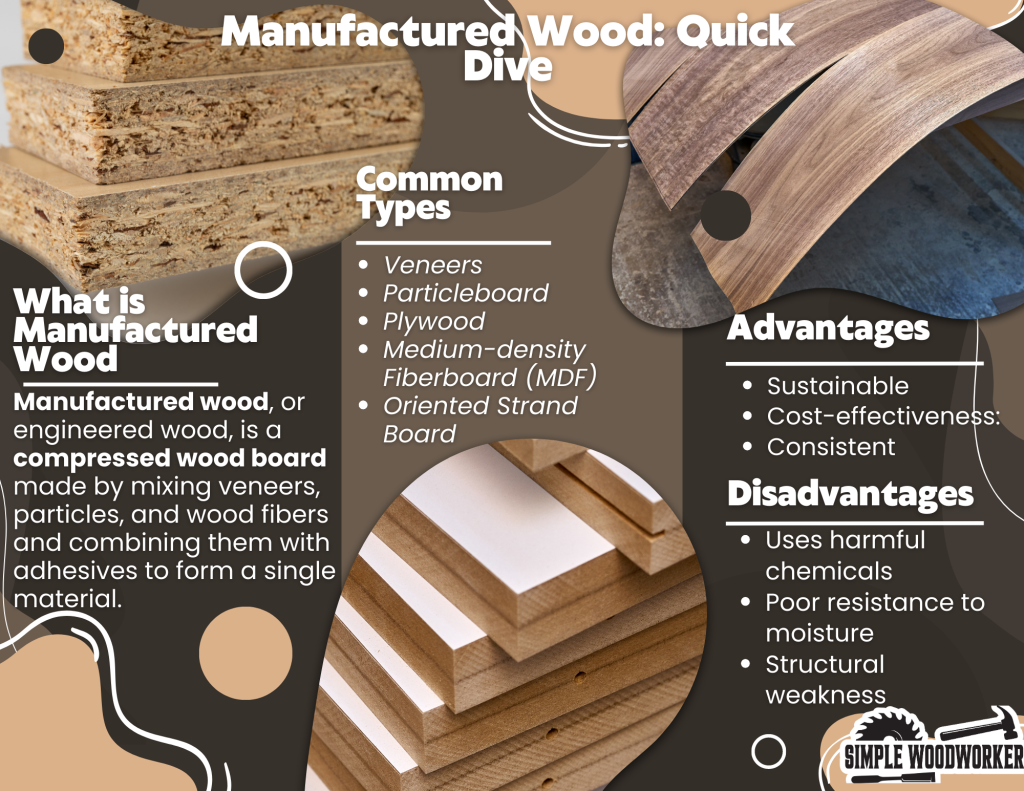

Manufactured wood, or engineered wood, is a compressed wood board made by mixing veneers, particles, and wood fibers and combining them with adhesives to form a single material.

Let’s picture a desk board made from manufactured wood. The top layer consists of real wood (also called veneers) covered in a thin protective layer of melamine. Closely following the real wood is medium-density fiberboard (MDF), or pressed board, stuck together with a strong adhesive.

Manufactured wood is a wood product. But we can’t call it real wood or veneers, so we call it wood composite.

Common Types of Manufactured Wood You’ve Probably Used

“What is manufactured wood made of?”. This question was second on my list after I had learned what manufactured wood even meant.

You can say manufactured wood hides in plain sight. Woodworkers use it to make desks, chairs, and even household cabinetry.

Here are some common forms of manufactured wood and their different characteristics:

Veneers

Veneers are thin slices of natural wood, which can be applied to other wood products to create a solid block. Like plywood, veneers have different qualities but they are all thinner than 1⁄8 inch.

Unsurprisingly, veneers are commonly used to make floors, ceilings, furniture, and artwork. Since they lean toward the more natural end, artists showcase their beautiful grain in exotic pieces.

Veneered products are perfect in scenarios where aesthetics are more important than product cost and weight. So, you should always prepare the wood properly and use it appropriately to avoid unnecessary accidents.

Particleboard

Particleboard is an inexpensive, low-density wood product made by combining sawdust, wood chips, and adhesives. It is popular among manufacturers who use veneers to make it stronger and stain resistant and improve its looks.

You’ll see particleboard in flooring, low-end furniture, false ceilings, and wood paneling. So, our guy has serious multitasking skills. But, particleboard is generally weaker than plywood or MDF, and its roughness gives woodworkers a hard time during staining.

To answer the age old particle board vs engineered wood debate, the winner will depend on the exact types of engineered wood.

What particleboard lacks in quality, it makes up for in cost. Its low cost makes it perfect for low-end furniture and small projects with budget constraints.

Plywood

Plywood, or laminated board, is the strongest known manufactured wood. Manufacturers create it by layering veneers until they have a strong and sturdy board. Basically, they stack the plies adjacently and glue them together under pressure.

Here’s the tricky bit – the quality of your plywood will depend on the parent veneer. But, quality plywood is good for roofing, cabinetry, flooring, and furniture making. And, its strength and anti-warp properties give it space in structural construction.

When buying plywood, you’ll see that it comes in different grades marked with letters of the alphabet. Higher grades look better and have fewer blemishes, and lower grades are more affordable.

Medium-density Fiberboard (MDF)

Fiberboard is actually a class of manufactured wood products made from a mixture of wood fibers and adhesives. So, there are several types of fiberboard with unique attributes and applications. MDF is denser than particleboard and other wood products so it is much more resistant to chipping.

To make MDF, manufacturers chop wood and heat them until they turn into fibers. Then, they dry and bond them to form a single board. We see fiberboard in insulation, soundproofing, roofing, and furniture.

As for downsides, fiberboard doesn’t hold nails well and flops in terms of water resistance. But, manufacturers and hobbyists love MDF because of its smooth surface, machinability, and excellent thermal insulation.

Oriented Strand Board

OSB is made by layering strands of wood and bonding them under heat and pressure. It is incredibly strong and rigid, making it the go-to product for building constructions. And, since it is derived from small fast-growing trees, OSB is a readily available product.

Oriented strand board is similar to plywood in many ways. It is less expensive and has a rougher surface, but isn’t usually recommended for high-end furniture.

What Are The Advantages of Using Manufactured Wood, Anyway?

Manufactured wood is steadily replacing solid wood in different applications. Here’s why:

- Sustainability: Woodworkers love manufactured wood because they can easily access it with much less impact on the environment. By choosing manufactured wood, we help shift demand and reduce deforestation.

- Cost-effectiveness: Affordability is one of the main perks of manufactured wood. Woodworkers can afford synthetic wood from low-grade or recycled wood products. Plus, you can manage your project’s overall budget by choosing manufactured wood.

- Consistency: Manufactured wood, like many man-made materials, is far more predictable than genuine wood. Natural wood varies in grain, which is unpredictable, and it might come with natural defects. So, manufactured wood is particularly beneficial to woodworkers who create on a large scale.

Are There Any Disadvantages of Manufactured Wood?

No doubt, using manufactured wood is amazing for woodworkers and the environment. But, manufactured wood isn’t without its downsides. Here’s why:

- Potential hazards: Manufacturers of engineered wood will often use urea-formaldehyde as a binder, which can release volatile organic compounds into the air. In poorly ventilated spaces, these VOCs are no good, because they can cause respiratory issues.

- Poor resistance to moisture: When manufactured wood is exposed to moisture, it absorbs and expands, causing it to warp. So, manufactured wood may do poorly in high-humidity areas like bathrooms and toilets.

- Structural weakness: Depending on the manufacturer, manufactured wood may not hold its ground structurally. Since its boards aren’t as strong as natural wood, they can sag and cave under heavy loads.

Manufactured Wood vs Solid Wood

Manufactured and solid have everything and nothing in common. They’re commonly used in the sample applications, so it can be tricky to differentiate them.

I prepared this side-by-side comparison, piecing them together as I worked with each product:

| Property | Manufactured wood | Solid wood |

| Sanding | The layers are thin, so you can sand twice maximum | Due to the thick grain, you can safely sand several times. |

| Price | Inexpensive | Expensive |

| Sustainability | Easy to produce, but may emit VOCs | Free from VOCs but will cause deforestation with high demand |

| Applications | Small woodwork projects and low-end furniture | Aesthetic woodwork and art |

| Installation | Easily to install, paint, and stain | Easy to stain, but may require an expert hand |

| Durability | Weaker than solid, and wear way due to thin layers and humidity | Can last for decades without significant damage |

| Weight | Lightweight | Heavyweight raw wood |

How To Handle Manufactured Wood: The Right Way

Warts aside, manufactured wood is the most popular choice for woodwork projects. And, when you factor in availability and cost, you won’t blame woodworkers for choosing it.

Instead of getting discouraged by the downsides, use this guide to take better care of your manufactured wood:

- Cutting and shaping: Because manufactured wood can be sensitive to cutting, always use high–quality blades to reduce the risk of splintering. Applying masking tape along the cutting line can also help you avoid chipping

- Joining: Manufactured wood and nails don’t really mix. Instead, use screws or dowels because they provide grip without damaging the wood. Also, remember to reinforce joints with appropriate glue (some manufactured wood products are picky with adhesives).

- Finishing: Take your time to sand down the surface and prime it with a fitting product. Then, stain in thin, even layers and glaze over with a clear top coat

Let’s Nail This…

Manufactured wood is simply a cookie made from cake leftovers. It is a wood product that consists of veneers, wood substitutes, and adhesives, all sandwiched together.

As an alternative to solid wood, manufactured wood is effective until aesthetics and durability are on the line. It still has woodworkers in a chokehold, though, because it is cheaper, more accessible, and much more accessible.

What do you think, stranger? Manufactured wood vs solid wood?

*This post may contain affiliate links. Please see my disclosure to learn more.