The simplest types of woodworking cuts for beginners are the crosscut and miter cut. But there are several more unique cuts for manipulating wood.

I’m a carpenter who has mastered woodworking cuts over the last 20 years. I’m an expert at cutting hardwood for my projects and even working in wood filler to fix pesky gaps.

Before starting this article, I consulted my 10-year-old woodworking journal and gathered my favorite types of woodworking cuts. Bottom line, I know seven crucial cuts to boost your woodwork and carpentry game.

Let’s get into it

7 Essential Types of Woodworking Cuts and Their Uses

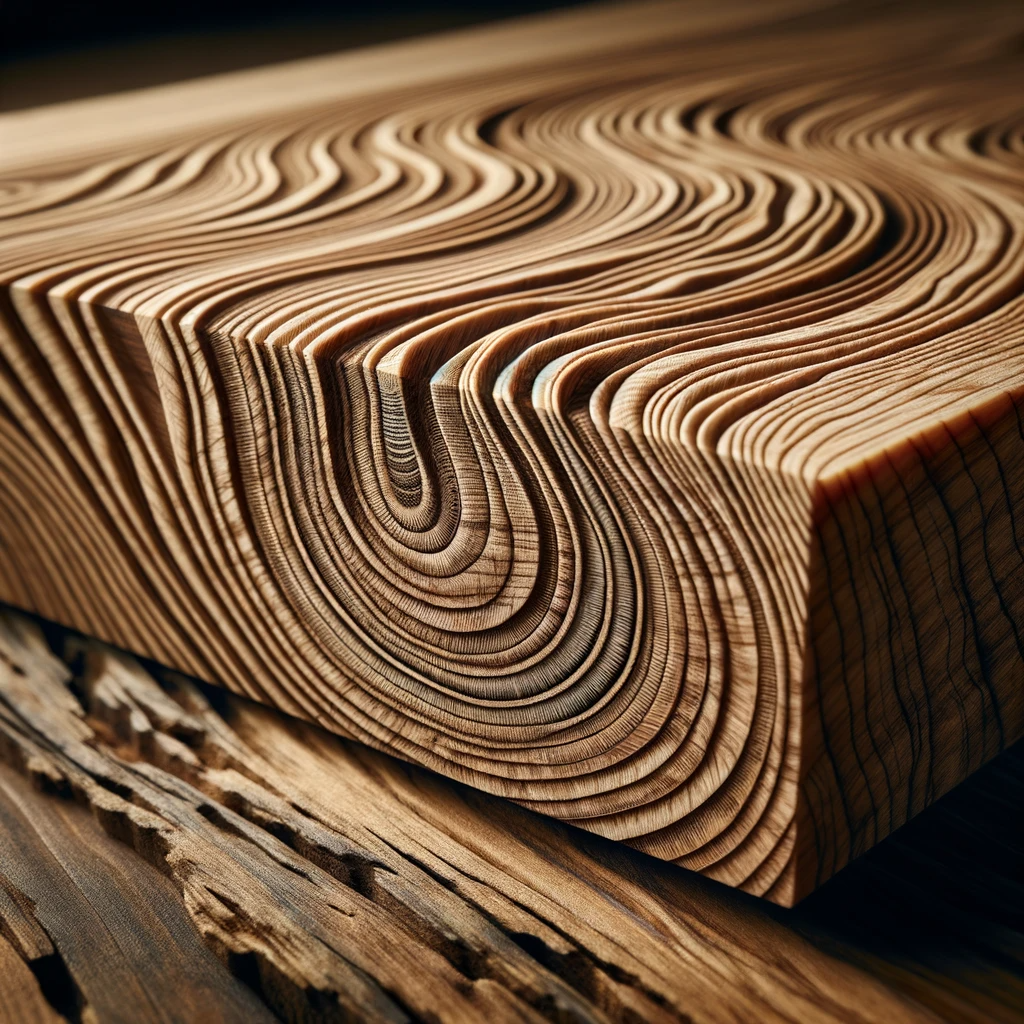

1. Live Sawn

Live sawn wood is the cheapest and most common way to cut wood.

Sawmills cut each plan off the log in one direction without changing orientation. So, it produces different boards with angles ranging from 0-90 degrees.

Live sawn planks display all the log’s characteristics. So, they work well in creating furniture for a rustic decor style. This method also produces the least amount of waste.

Uses of Live Sawn Lumber

- To create hardwood floors that show off the wood’s natural characteristics

- To create highly durable furniture (due to the combination of radial and tangential grains)

- To provide a wood source that is cost-effective and environmentally friendly

2. Quarter Sawn

Quarter sawn planks have a straight grain that runs vertically across the wood.

To achieve the cut, sawmills divide each log into quarters. So, the planks are usually below 6 inches. However, these planks are more expensive than live sawn wood because the process generates much waste.

Uses of Quarter Sawn Lumber

- To create hardwood floors that won’t cup or warp due to humidity

- To create staircases, balusters, and handrails that withstand wear and maintain their appearance

- To craft high-end furniture that is stable and less prone to contraction and expansion

3. Rift Sawn

Rift sawn lumber is the rarest and most expensive woodworking cut. Like quarter-sawn planks, it is cut perpendicular to the tree’s growth rings to create a linear grain.

However, the rift sawn method is extremely wasteful. It discards the heartwood in favor of the sapwood, so you’ll rarely see rift sawn planks wider than 4 inches. That being said, rift sawn planks are a luxury lumber.

Uses of Rift Sawn Lumber

- To restore and replicate period-specific furniture

- To make high-end flooring with rift sawn oak

- To make mission-style cabinets, islands, and shelves

4. Rip Cut

A rip cut is made by cutting along the length of the board.

The aim is to split the wood along the grain as you cut the wood into narrow strips. Carpenters perform rip cuts to reduce the log’s width and create strips.

So, think of spitting a log into firewood with an axe. A rip cut follows the same principle, only much cleaner.

Uses of Rip Cuts

- For creating horizontal rails and vertical stiles for the cabinet’s framework

- For fighting planks properly against the wall

- For sizing lumber into wall studs for framing

5. Curve Cut

A curve cut requires you to cut the wood along a curved path rather than a straight line.

Unlike rip cuts, cross cuts are purely decorative. So, you can use it to cut waves, contours, and waves.

The most effective tool for making a cross-cut is a circular saw. Its continuous and narrow blade moves in a loop, so you have better control over complex shapes and curves.

Uses of Curve Cuts

- For softening curved edges on cabinet doors and table tops

- For creating curved profiles like cabriole legs

- For removing knots in wood

6. Miter Cut

Miter cuts are angled cuts across the width of the wood. They are made precisely at a 45-degree angle to form a 90-degree corner, but you can also create a miter joint from any angle other than 90 degrees.

Many carpenters use a power miter saw, to help them make quick and accurate miter cuts. But you can also use a handsaw as long as you have some form of stencil.

There are many wood hand saw types, but my go-to is the Olympia Tools Mitre Box. It comes with a handy plastic saw box with different angles, which helps me make angled cuts better.

Uses of Miter Cuts

- For joining custom furniture to make interlocking corners

- For creating picture frames with wood

- For installing interior trim and molding around a corner

7. Crosscuts

Crosscuts are made at a 90-degree angle perpendicular to the grain. So, these types of woodcuts run straight along the log’s width.

Depending on the level of precision you need, you can use crosscut saws and even miter saws for the crosscut. Both of them serve the same purpose in this application.

I always use a straight-edged crosscut saw and some solid foam insulation to avoid damaging the blade.

Uses of Crosscuts

- For cutting large boards into more manageable lengths

- For cutting cut large timber logs at a straight angle across the grain

- For cutting interior trim pieces like baseboards, door casings, and crown molding

The Ultimate Cut

All the different types of woodworking cuts work to serve one purpose: to create unique planks for woodwork. Every cut specializes in a unique style that you can use to create anything from traditional Amish to contemporary American furniture.

If you’ve decided to take these techniques to the workshop, then you should explore Japanese wood saws. I’ve written an article covering the best Japanese hand saws in the market, so be sure to check it out!

What is your best pick from these types of woodworking cuts? Tell me your hot take in the comments and share this article with your favorite woodwork buddy.

Frequently Asked Questions

What Are The 4 Types of Wood Cuts?

The primary types of cuts in wood are live sawn, plain sawn, quarter sawn, and rift sawn. Every cut has a distinct appearance and method, so it varies by cost. Essentially, the less wasteful the cut is, the cheaper and more common it will be. So, rift sawn and quarter sawn cuts are the most wasteful and expensive cuts.

What is The Strongest Cut of Wood?

The strongest cut of wood is rift sawn lumber. Sawmills cut the planks perpendicular to the tree’s growth rings, resulting in an extremely linear grain pattern. Rift sawn lumber is also the least common and most expensive cut of wood.

What is the Most Common Wood Cut?

The plain sawn technique is the cheapest and most common wood cut for hardwood applications. Sawmills cut the planks, turn them 90 degrees, and cut them again to create a loopy grain pattern.

*This post may contain affiliate links. Please see my disclosure to learn more.